| Home | Contents | Start | Prev | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Next |

Test Runs with new Cutting Motor

I finally managed to test the new cutting motor. The good news is that the battery life has been dramatically improved, I'm seeing over an hour of mow-time easily although I've not measured the total achievable.

The grass was rather wet during testing and although there seemed to be lots of grass cuttings being ejected from the back of the mower, I was not seeing the narrow strip of mown grass that was apparent with the previous motor. It could be the wet grass, I did not use the old motor on wet grass but I suspect the slower rotational speed means some of the younger grass bends rather than gets sliced. Regardless of how wet the grass is, Lawna should still be able to cope so some changes are needed.

Blades Revisited (Yet Again)

The new cutting motor rotates considerably slower but still at 2000 rpm. It also has twice the torque of its predecessor. If I were to make the blade larger, the tips of the blades would have a much faster linear speed over the ground so I might get back some of the advantages of the original motor. Also, as it has taken me so long to develop this mower, the girls have got quite used to not going near the blades so another option is to grind a sharper edge to aid cutting, especially nearer the hub. If I go down this route, I need to make the foot bumper more robust to ensure it does not come off.

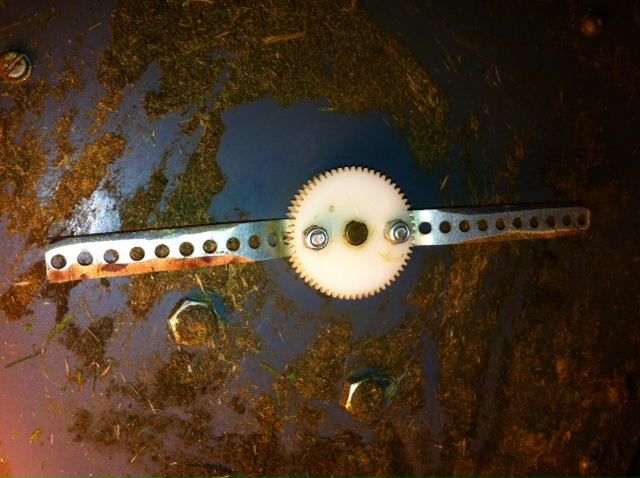

I ground an edge onto the existing blade to see how it fared. The answer is very well :-). Lawna was happily cutting 4cm wet grasss and flinging it out the back. The locomotion wheels struggle in this length of grass as after-all, that is not what the mower was designed for. So a slower blade with more torque required a sharper blade and we get a great battery saving, well over 1.5 hours and still going. I'm hoping that on shorter grass, we will get over two hours. Here is yet another picture of a mower blade !

Foot Bumper Revisited

The foot bumper is made up of semi-rigid plastic strip that is attached to two long-arm microswitches. This works pretty well most of the time but it is only held on as strongly as the lever-arms of the microswitches. The bumper can ping off if a branch from a shrub gets under the bumper when the mower is backing away. If I am going to make the blade both larger and sharper, I need to ensure this does not happen.

The chosen solution is to use two bolts through the bumper and mount them on fixed supports. The bolts use compression springs to hold them away from the microswitches. There is therefore no mechanical connection between the bumper and the switches as the bolts and their mountings handle that. There needs to be enough 'slop' so the bumper can activate left, centre or right switches so as to make the appropriate avoidance action. It took a bit of experimentation to find springs that were sufficiently string to hold the bumper rigidly but not too strong to prevent the switches being activated on contact.

It was possible to remove the microswitch levers totally and the bumper is mounted very close to the front of the chassis thereby fixing an earlier issue where twigs could sometimes get caught between the bumper and the chassis when backing out of a bush. I spent 30 minutes directing the mower under one bush after another and it managed to get out of trouble easily, without the bumper getting caught. Here is the idea:

And this picture shows it mounted on the mower. (Yes glue again, but I needed to minimize the number of grass-traps under the mower and bolt-heads are exactly that !

Software Updates

I have not made any software updates for a long time but as the project nears completion, it is time to start adding minor adjustments made by observing the mower's actions and situations where it gets into trouble.

One problem area I see is when Lawna gets stuck in a pothole or hits a horizontal spike that sits above the bump sensor and below the eyes. Currently she will keep going forward, spinning wheels and generally being pretty stupid.

As the mow pattern is already random, a bit more randomness will do no harm. I aim to add a tweak that throws in a random reverse and/or turn every N seconds so that if the mower ever gets in the state of pushing against an immovable object, it will try various exit strategies and hopefully get out of trouble. It will make the normal mowing pattern rather erratic but at least it is planned erratic behaviour, unlike some of my initial test runs!

When, (a long time downstream), I add homing behaviour, I will need to disable this randomness but I think I will need a re-write by then and may turn the whole program into a finite state machine to aid testing.

Results

Changing the cutting motor be a lower power, higher torque variety has increased battery longevity considerably. The slower speed of rotation did effect cutting efficiency but grinding the blade to give it a sharper edge solved that. The sharper blade meant the front bumper needed to be more sturdy and in the process of redesigning it, one area where the mower could get stuck (reversing out from a bush) was also solved.

An fortunate side-effect of the slow rotational speed is a less annoying whine (like a strimmer) coming from the mower, the main noise now comes from the drive wheels.

I'm happy with Lawna as she stands, it is possible to let her loose on the lawn and she trundles around weaving this way and that, dives under bushes and comes out chewing leaves. The battery life is now very good and the trickle charger, breathes life back into the batteries in-place. It's unfortunate that we are now at the end of the summer and a lawnmower is unlikely to be very useful for several months but we are ready for next year!

I'm going to close off this project now and turn my attention at homing and docking mechanisms so Lawna may well get a refit in the future, but that is a job for another day.

September 2013

| Home | Contents | Start | Prev | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Next |