| Home | Contents | Start | Prev | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | Next |

Collision Sensors

Microswitches lend themselves well to collision sensors and I used these to good effect with Lawna. Lawna had a single straight bumper but for Mo, I will need a rounded bumper that activates when hit from several directions. There is part of me that thinks I could use the copper pipe that is to be the aerial for the perimeter detector and this is worth consideration. However, I like the idea of mechanical as well as electronic separation of the sensors so I decided to build stand-alone bumper mechanism.

Previous experience revealed that the bumper needs to be mechanically sturdy, and spring loaded to prevent damage to the microswitches. It may be possible to use resistance wire or a whole host of other technologies but in the first incarnation, a simple solution will suffice.

Three microswitches will be used, one at the front, and one on the left and one on the right. This will give data on which switch has been activated and the robot can take the appropriate avoidance action. The bumper is made from aluminium strip and held away from the switches by tensioned mounts, which recoil when hitting an obstacle.

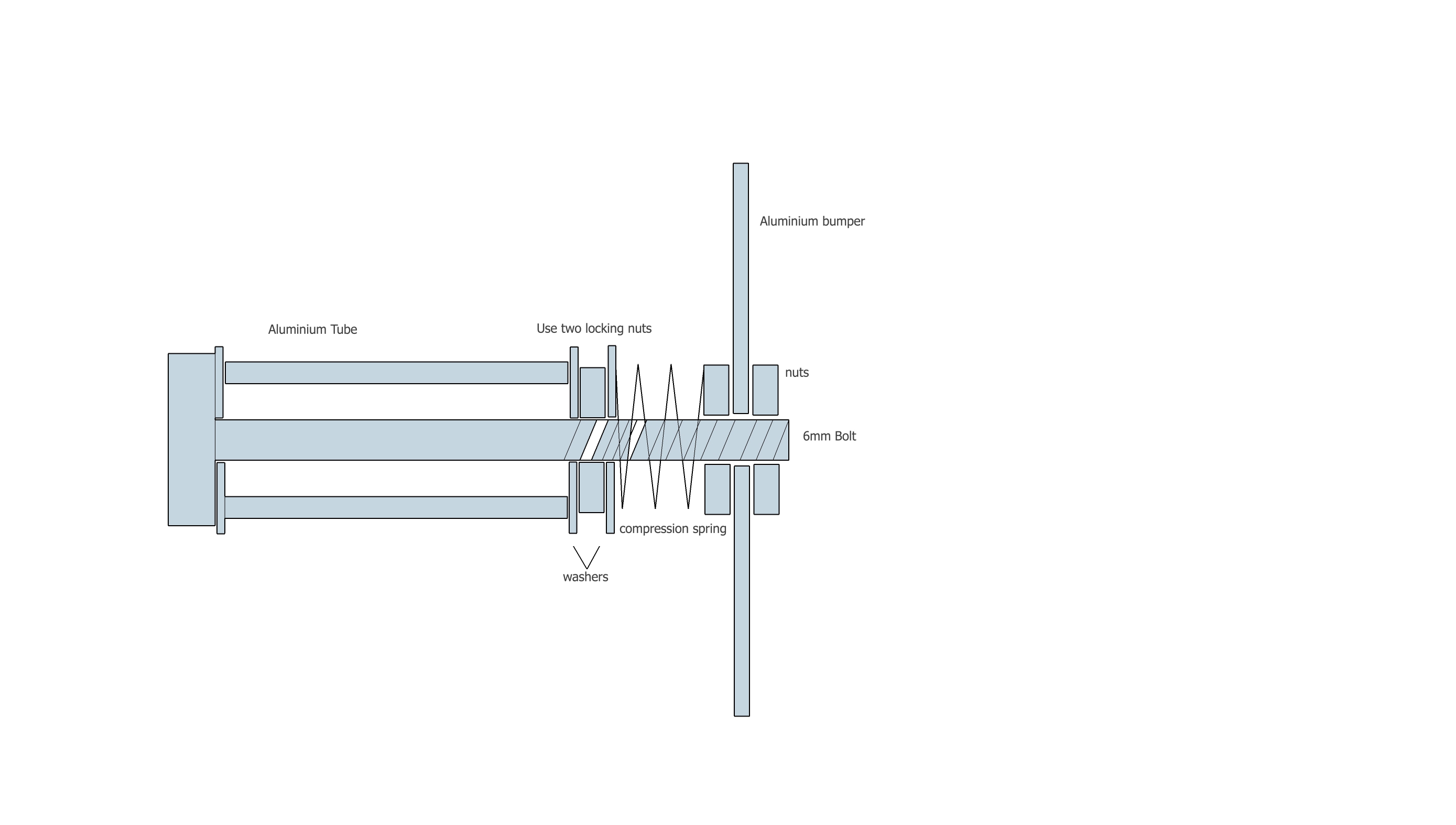

No readily available bumper mounts were available so I made my own based on the design below. In practice I swapped out the aluminium tube for steel brackets as I could weld steel more easily than aluminium.

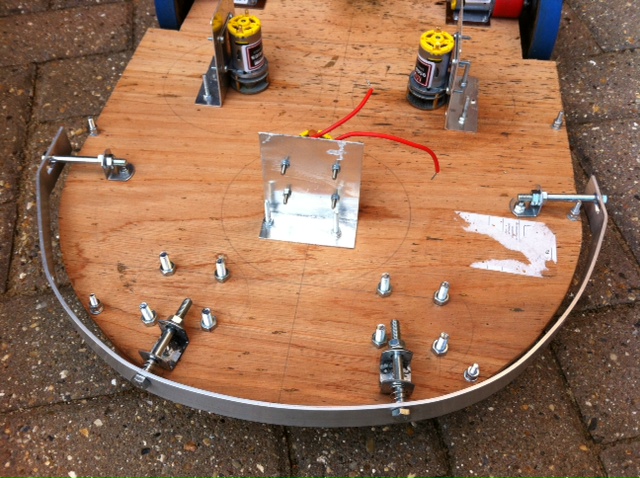

And here is a picture of the actual spring-loaded bumpers

An aluminium bumper was made that wrapped around the front of the machine as shown.

The main mechanical side of the lawnmower construction is now complete. It will be necessary to mount micro-switches near the bumper, secure the battery and electronics, and start thinking about a cover, but these will all fall into place once the electronics and software are in order.

August 2014

| Home | Contents | Start | Prev | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | Next |